Alloy Wheels Buying Guide

28th November 2018 | By Malcolm Carter

What are "Alloy wheels"?

In the not too distant past most cars were fitted with "steel wheels" as standard. Cheaper to produce, heavier, smaller dimension and tidied up with a cheap plastic wheel trim clipped on the front. Premium models of vehicles and car styling enthusiasts upgraded to alloy wheels which were bigger, lighter and available in a wide variety of styles. Even though the need to replace old steel wheels is not as great as it used to be, people are still looking to upgrade their alloy wheels for a variety of reasons; improve the appearance by ditching dated or poorly maintained old alloys, increase the size of the wheels for luxury and high performance styling, a spare set of 'winter wheels' for use in months where snow and ice are more likely, or to just replace wheels damaged by pot holes which can often be cheaper than buying a single original alloy wheel from a manufacturer such as BMW or Mercedes.

The mix of aluminium in the 'alloys' makes sure the wheel is lighter and can be moulded into the cool designs you see on this website, whilst retaining the required strength. All our alloy wheels are tested to the highest safety standards and we make sure that every single set we sell is exactly the right specification for the intended vehicle - which includes heavy and commercial vehicles like a Volkswagen T5 or 4x4 pick ups.

Open spoked designs allow for greater cooling of the brakes on performance vehicles and also makes them easier to keep clean from corrosive brake dust.

Bigger wheels can sometimes mean wider wheels and therefore wider tyres and better grip. Carnoisseur can offer specialist advice for the size of wheels that would best compliment the specific make and model of vehicle to ensure stunning good looks and top performance. You can filter to alloy wheels that fit your specific vehicle by clicking here and using the red selection box at the top right of the page.

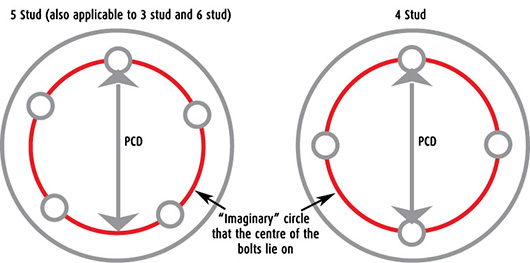

What is a PCD?

PCD stands for 'pitch circle diameter' and is basically the measurement between the bolt holes. It is vital that the alloys have the same PCD as the vehicle's wheel hub. It is calculated from the diameter of a circle that is drawn through the middle of the holes. Carnoisseur have details of the PCD for every make and model of car and the website uses this information when recommending wheels that fit your vehicle. If in doubt, then please call the specialists on 01582 787377 or visit one of our fitting centres nationwide.

Sometimes, people would like to fit a specific style or set of alloy wheels to their vehicle that require a different PCD to their vehicle’s existing hub. In these cases it can be achieved by fitting PCD adapters to the hub before fitting the wheels. These are precision engineered hub-centric spacers that provide, in effect, a new wheel hub. This is particularly popular for fitting Porsche wheels onto classic or modern Volkswagens such as a Beetle, Golf or T5 Transporter. You can view the range of PCD Hub Adapters from H&R by clicking here.

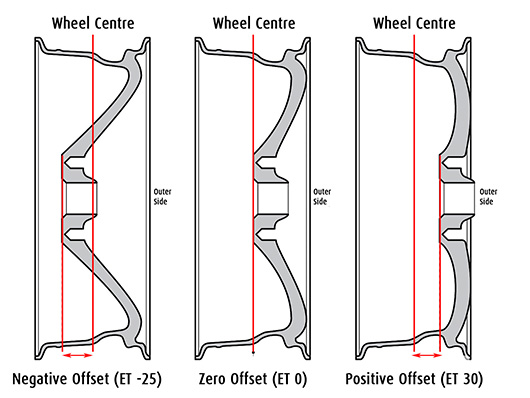

What is an offset?

The offset is the measurement, in millimeters, between the hub face on the back of the alloy wheel and the centreline of the wheel width. Sounds technical, hey? Basically, the lower the offset, e.g. 15mm, the bigger the protrusion of the metal hub in the back of the wheel and the further out the wheel face protrudes from the vehicle's wheel hub. Carnoisseur will always check the offset of the wheels supplied for the intended application and make sure everything will fit perfectly.

The Offset of a wheel is usually stamped or engraved into the alloy on the inside surface or hub and starts with 'ET'. ET is short for the German 'Einpresstiefe' which literally translates as 'insertion depth'.

Hubcentric wheel spacers can be used to increase the offset, either to fit specific wheels or make the wheels move out closer to the wheel arch for aesthetic or performance improvements. Carnoisseur supply a full range of fully tailored and high precision engineered hub-centric wheel spacers plus extended bolts or studs, if required. Always best to ask the professionals before purchase, especially if you're unclear on exact requirements, costs and implications. We're here to help make it simple.

What is a centre bore?

The centre bore is the width, in millimetres, of the central hole in the back of the alloy wheels and, therefore, the diameter of the vehicle's wheel hub. It's vital that the centre bore of the wheel matches the car precisely, otherwise you will experience vibrations through the steering wheel when driving - no one wants this and it can be dangerous! The centre bore of the wheel is sometimes modified to match the vehicle by using spigot rings which safely adapt the wheel to the hub size. They are simply placed snugly into the back of the wheel when fitting. Again, these will be supplied with the wheels, free of charge, if required.

Fitting a new set of alloy wheels

Obviously getting a trained mechanic to fit your wheels is quicker and easier, but if you fancy doing it yourself here is a quick guide to help get it right first time.

First thing first, make sure you have all the correct fitting equipment and accessories: sturdy jack suitable for the vehicle, correct wheel wrench to fit and new nuts or bolts head hex size, new nuts or bolts that have the correct 'seating' for the wheels, locking nuts or bolts with key, spigot rings where required. Most alloys have a 60 degree 'seat' in the bolt holes, which should match the taper of the seat on the nuts or bolts - check carefully that this is the case. The seat could be flat or radiused, or collars might be required.

Make sure the car is on a flat surface, in park (for automatics) and handbrake applied. It's also wise to chock wheels in contact with the ground to prevent any movement, blocks of wood could be used. Jack the car, loosen the bolts whilst the old wheel is still in contact with the ground and then raise the car to give clearance beneath the wheel. Then continue to loosen and remove the existing bolts. Remove the wheel carefully - they are heavy and can sometimes be seized onto the hub which will take some extra effort to loosen. Once removed, clean up the centre hub and apply some grease if required. Next, offer the new wheel up to the vehicle to check the centre bore of the wheel (the hole in the middle of the back of the wheel) fits tightly onto the wheel hub. Sometimes plastic rings, known as spigot rings, are used to make sure the wheel locates snugly - make sure you use them if supplied. Carnoisseur will always ensure the correct new spigot rings are supplied with wheel orders. Likewise, check that there is clearance between the wheel and the suspension, brake caliper and wheel arch. Carnoisseur will only recommend wheels that fit perfectly, but modifications to brake caliper and disc size, coil-over suspension or lowering springs can all make a big difference here - it's vital that such mods are mentioned when ordering and checked thoroughly when fitting.

Next, make sure the tyre is rotating in the correct direction. Directional tyres will have a marking on the side wall to indicate the correct direction. Once the alloy wheel is located on the vehicles wheel hub, make sure the bolt holes line up and then use the new bolts to fit the wheels. There are some cool wheel alignment tools that help make this process really quick and easy. If your vehicle has studs (threads fitted to the car wheels hub) then this makes alignment very simple, just make sure the studs are long enough for the new alloys ensuring at least 4 full rotations of the nuts onto the thread.

Tighten all four of the new fittings and then lower the wheel onto the floor carefully with the jack. Once in contact with the floor retighten the fittings. It is advised to retighten the fittings again after the car has travelled approximately 30 miles.

Once all four have been done, then hey presto, you're ready to roll!

Staggered or split width wheel sets

Sometimes it is possible, even advisable, to fit wider wheels on the back axle than on the front. This is usually the case on BMWs, Audis, Mercedes and Porsche, for example. This is often known as 'staggered' fitment or split width sets. This provides greater grip to the back of the car on rear wheel drive models.

What are Winter wheels and tyres and why should I use them?

It's been popular on the continent for a very long time, but severe winters in the UK has made this a growing trend for our customers. Winter tyres offer a higher mix of natural rubber and silica compound in the rubber and, as a result, perform far better in snow and ice - improving road holding and decreasing stopping distance. Winter tyres also have a deeper tread to account for the conditions. Changing tyres is a pain and often quite expensive. Therefore, customers often opt to buy a set of new alloy wheels pre-fitted with winter tyres which can be stored during the Summer and fitted in early Winter and removed again come Spring. Carnoisseur offer robust wheel storage bags to protect the wheels whilst not on the vehicle. Swapping to Winter tyres also has an added bonus of protecting your beautiful Summer wheels from the damaging effects of road grit and salt which can pit the surface of wheels and also save the tread which wears quick when wheels spin in slippery conditions. Winter wheels often have tougher coatings on the alloy to stand up to the elements.

Winter wheels are usually slightly smaller in diameter and width, again to aid performance in wet and slippery Winter conditions. This has an advantage of being slightly cheaper making safe Winter driving more affordable. Carnoisseur will offer full advice on the best make and size of wheels and tyres to suit your specific vehicle so head over to the contact us page to get in touch. You can view the suitable Winter alloy wheel options by clicking here too.

Can I use Winter tyres in Summer?

You can, but it's not advised and here's why. The silica compound makes the tyres for flexible and stay softer and stickier in freezing conditions. This is great in the cold, but means faster wear on hot dry tarmac. Save the tread for when it's needed most in Winter months. Standard summer performance tyres are designed for higher heat and will last longer, plus offer lightning fast response and low noise levels - softer Winter tyres are not quite as ideal for performance here.

How to clean alloy wheels

Now, you've invested in beautiful new rims - let's keep them looking pristine. Regular cleaning of your wheels is strongly advised to make sure that corrosive brake dust and road grime doesn't build up and start to etch unsightly pits into the lacquered alloy wheel coating. Likewise, think carefully about the product you use to clean the wheels as sometimes they can contain acid which is harmful to the finish of the rims. This is all even more important if your new alloy wheels have a polished face or chrome finish as the metal is more exposed to corrosion.

Here are some tips:

- Wash your wheels first when cleaning the car. This will stop the corrosion black brake dust and road grime spraying onto the clean bodywork and also the added benefit of washing away the black wheel dirt from the driveway as you rinse the rest of the car. 2. Rinse the wheel liberally with clean water. If using a pressure washer or hose then spray inside the wheel arches to remove any mud build up. Be careful though, don't use a harsh high pressure that can strip paint off surfaces! 3. Spray each wheel with an environmentally friendly and non-acidic alloy wheel cleaner such as Muc-Off Frequent Wash Wheel Cleaner, Poorboys Spray & Rinse Wheel Cleaner or Meguiar's Hot Rims All Wheel Cleaner to loosen and brake down the dirt particles. Make sure you include the bolt hole recessed and spoke crevasses.

- To help remove stubborn patches agitate the cleaner with a soft bristle cleaning brush that won't scratch the alloy wheel surface. A good example is the Muc-Off Wheel & Brake Brush or Kent Alloy Wheel Brush, both of which are study yet flexible and perfect size to get between spokes.

- To get into the bolt holes a detailing brush such as Muc-Off Two Prong Brush can be helpful to get a perfect professional finish in tight spaces.

- Rinse the wheels again with clean water and wipe down with a soft microfibre cloth such as a Kent 2 in 1 Wash Mitt Microfibre Noodle.

- Once dry, protect the alloy wheels with a sealant or wax. There are plenty out there to choose from such as Poorboys Wheel Sealant. This will help keep the alloys sparkling and also help repel new brake dust sticking to the surface. Most should be suitable for all wheel surfaces such as painted, polished, chrome and lacquered.

Protecting your new alloy wheels

Stunning alloy wheel rims are an eye catching addition to any car. Sometimes you can catch the eye of the wrong admirers and so how do you make sure that the wheels remain firmly fixed to your vehicle and not in the hands of the car criminals?

First, make sure you have Thatcham Approved locking wheel nuts or bolts fitted. Thatcham is a quality assurance level that has been tested to withstand strident attempts to remove them by force. All of the locking nuts and bolts Carnoisseur supplier are fully Thatcham approved. Next up, make sure the locking key is not in an obvious place in your car. Thieves can often break in and check the glove box or boot for a locking nut key to make their life of crime very simple. Hide the key in a safe place, but keep it within the vehicle somewhere - last thing you want is to get a puncture on the M6 and not be able to change the wheel!

If, by some extreme unfortune the determined thief still manages to steal your wheels, then at least make sure you're covered and not out of pocket. Alloy wheel upgrades should be declared on your car insurance policy so that you remain fully covered and reimbursed the full amount in the unlikely event of a theft.

Aside from protecting from theft, it could also be wise to protect your new alloys wheels against kerb damage. It's very easy to scrape the outside edge of a wheel on the kurb, especially when parrellel parking in a hurry. A set of four alloy wheel rim protectors is a sensible idea and there is a product called an AlloyGator that fits between the tyre and alloy rim to add a layer of protection and is also available in a large range of colours - one option even glows in the dark! Starightforward to fit and suitable for wheels size 12" to 24" in diameter.

Now you know all about alloy wheels, to work out if your tyres would fit your wheel, or to compare fitments, check out our handy wheel calculator.