Our no quibble lifetime warranty, guarantees these Forged bolts

for the lifetime of your vehicle.*

No quibble lifetime warranty.*

Introducing the Forged Locking Wheel Bolt Set for the Genesis Electrified GV70.

This complete kit includes 4 Thatcham Approved high-security locking wheel bolts available in a silver finish. It also comes with a set of Black protective caps for the locking wheel bolts, and a purpose-designed cap puller that can be stored neatly alongside the locking bolt key in the supplied storage case.

To make wheel fitting easier, we’ve also included a wheel alignment tool, helping you line up, support, and refit your alloy wheels quickly and safely.

All of our Forged locking bolts are produced to ISO14001 and TS16949 quality standards. The raw materials are inspected to ensure the structural integrity of the complete lock, and every bolt is through-hardened and tempered. The plating process includes several layers of nickel and one layer of microporous chrome producing a superior finish that looks great and also protects against rust.

This rigorous manufacturing process produces bolts that are original equipment standard, in fact the same bolts are used worldwide by over 20 different car manufacturers!

Available exclusively at Carnoisseur, the Forged Locking Wheel Bolt Set for the Genesis Electrified GV70 comes with a no quibble lifetime warranty, guaranteeing the bolts for the lifetime of your vehicle*.

Please note that these locking wheel bolts are designed for use with original equipment alloy wheels only. Please contact us if you have aftermarket wheels fitted - we will be happy to help.

What's Included

- Set of 4 Thatcham Approved silver locking wheel bolts for original equipment alloy wheels

- Set of protective black locking wheel bolt caps

- Specifically designed puller to remove the locking bolt caps

- High tensile locking wheel bolt 'key'

- Durable plastic case for locking bolt key and puller

- Self-adhesive locking bolt key code sticker (please note that it is important you keep a record of the key code in case you require a replacement key in the future)

- Wheel alignment tool for easy fitting of your alloy wheels

The bolt caps supplied are black

Wheel alignment tool - helping you line up, support, and refit your alloy wheels quickly and safely

Spot The Difference

A fresh set of wheel bolts can make a surprisingly big difference to the overall appearance of your wheels. Old bolts that have become rusty, or have cracked and peeling paint, can really stand out and spoil the look of otherwise pristine alloy wheels.

Replacing them with a new set of high-quality Forged bolts won’t just keep your wheels securely fitted and your car safe – their hard-wearing protective finish adds the perfect finishing touch. And with our lifetime warranty*, you can be confident they’re built to last.

Before - Porsche Cayman alloy wheels with old, rusty bolts

After - alloy wheels with new Forged bolts and locking bolts

Will These Definitely Fit My Car?

This locking wheel bolt set is designed specifically to fit your Genesis Electrified GV70. Several factors are taken into consideration including:

- Wheel bolt thread

- Pitch

- Thickness

- Seating

- Length

- The strength of the material (to be able to take and exceed the required torque setting)

- Hex size (to fit the original equipment wheel brace supplied with the car)

As long as you have selected the correct vehicle you can rest assured that it will fit perfectly. If you're not sure which kit is suitable for your vehicle, please contact us and we will be happy to help.

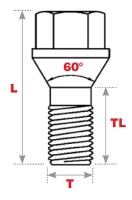

Technical Specifications

- Thread (T): M14x1.5

- Thread Length (TL): 27mm

- Overall bolt Length (L): 52mm

- Locking Key Outer Diameter: 29mm

- Hex size: 17mm

- Seating: 60 degree

Note: this is for vehicles which use 5 bolts per wheel.

Each Forged Locking Wheel Bolt Package is engineered for a specific vehicle fitment. The original equipment wheel size, stud pattern, seatings, hex are all taken into consideration.

Please note that the thread value shown is the diameter of the threaded section, measured across the shank at the outer edges of the thread (e.g. "M12" refers to a 12mm diameter), followed by the thread pitch (e.g. "1.25" is the number of threads within a 10mm section, so if there are 8 threads within a 10mm section, the pitch is 1.25).

It is extremely important that your bolts seat properly in the holes in your wheels, in other words the profile of the head of the bolt needs to match the profile of the inside of the hole exactly. Some wheels require bolts with a 60 degree tapered seating, some need a radius seating and some need a flat seating. Our wheel bolts have the correct seating for your original equipment alloy wheels. Please be aware that the vast majority of aftermarket wheels require a 60 degree tapered nut or bolt.

How Are They Made?

All Forged wheel nuts and bolts are manufactured to the very highest standards. Each batch of raw material is carefully inspected to ensure complete structural integrity, and every part is through-hardened and tempered for maximum strength and durability.

To achieve a premium, long-lasting finish, the bolts are plated using multiple layers of nickel followed by a final layer of microporous chrome. This not only looks superb, but also provides excellent protection against corrosion.

This rigorous process results in bolts that meet original equipment standards - in fact, the very same bolts are used worldwide by over 20 different vehicle manufacturers.

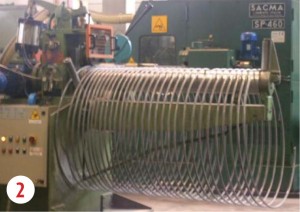

Raw material is prepared for cold forging and turning. Inspected and checked before being processed.

Beginning of the bolt production process - raw material being prepared for the forging machine.

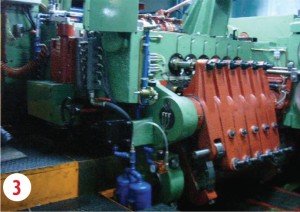

State of the art cold forging machine which produces the wheel bolts.

Turning machines for the production of wheel nuts and various components.

Heat treatment plants for hardening the lock body and components.

Induction hardening equipment to maximise the lock head strength and resistance.

Automated thread rolling machine for precision threads.

State of the art plating process. A variety of finishes are available.

Dehydrogenation process.

On site metallurgy testing facility for quality control.

Installation Advice

Wheel fittings are a safety critical product. If you have any questions or concerns please talk to a qualified mechanic.

- After fitting any of our wheel parts and accessories, we strongly recommend that before the vehicle is moved or driven, each wheel that has been worked on should be turned through 2 or 3 complete revolutions. This is to ensure that no parts foul or obstruct the brakes, suspension or interfere with the smooth turning of the wheel.

- We also strongly recommend that the wheels are turned to full lock both left and right to ensure they do not foul any part of the vehicle.

- We recommend that a visual check is made when removing the original nuts or bolts. Check that replacement nuts or bolts are an exact match. Wrongly fitted locks or replacement nuts or bolts may cause damage to the wheel hub and/or braking system.

- All vehicle manufacturers recommend a torque setting for their wheel fixings. It is usually between 90-125 Newton Meters (Nm) depending on the size and weight of the vehicle. Larger heavy vehicles such as 4X4s, light commercials, vans, pick-ups etc. will probably have a higher torque setting somewhere between 140-190 Nm. Always check the vehicle manufacturer’s recommended torque settings before tightening any wheel fixings. This information should be available in the vehicle manufacturer’s handbook. If not you should consult the relevant main dealer or a qualified mechanic.

- Do not use a pneumatic impact wrench/air gun to tighten or remove wheel locks. Do not over tighten.

- Ensure the key is always fully engaged on the head of the wheel lock before torque is applied.

- Check the tightness of all nuts or bolts that have been worked on after the first 100 miles and periodically check tightness of all nuts or bolts.

- Always apply the handbrake at all times when working on a vehicle.

* The warranty covers defects in materials and workmanship of your Forged bolts, for the lifetime of your vehicle. The warranty is void if the products are damaged by an accident, unreasonable use, neglect, misuse, abuse, improper installation or other causes not arising out of defects in materials and workmanship. All products are fitted at the purchasers' own risk. We do not accept responsibility for improper use, improper installation or unsafe installation, illegal installation or unsafe installation. Please note that the use of acidic and alkaline wheel cleaners that aggressively attack the coating of wheel locks, wheel fixings or wheel accessories will constitute misuse.